| Name | Download |

|---|---|

| HL Product List.pdf | Download |

| Availability: | |

|---|---|

| Quantity: | |

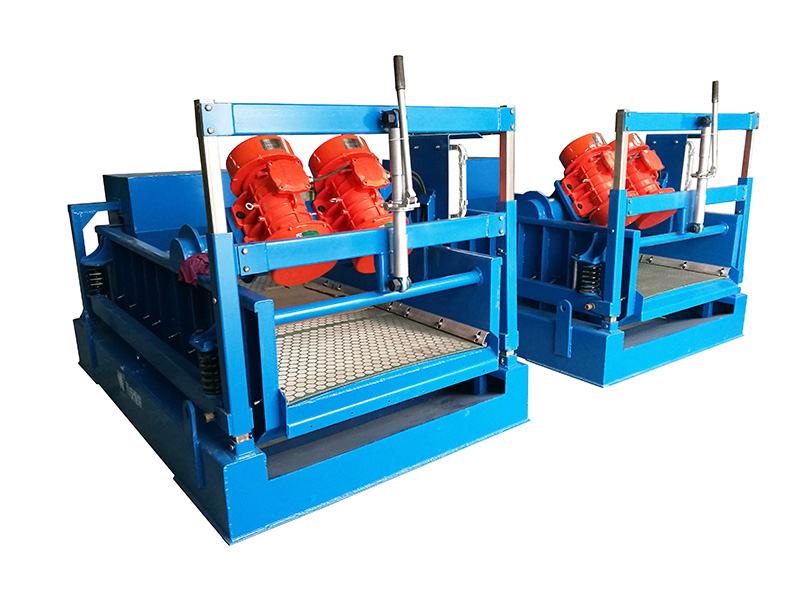

Overview of linear shale shaker

Linear mud shale shaker is a first-stage equipment for solid-liquid separation of drilling fluid. It is suitable for drilling fluid solid control system of oil and gas drilling. Linear movement along a certain direction achieves the purpose of screening and discharging cuttings particles in drilling fluid.

Features of linear shale shaker

1. High efficiency of linear vibration trajectory.

2. Any combination of double, triple and quadruple.

3. The angle of the screen box can be adjusted to prevent the slurry from running out.

4. Hook edge plate screen, economical and affordable.

5. Screen box inclination adjustment device to prevent pulp running.

Technical parameters of linear shale shaker

Model | HZS703 | HZS803 | HZS604 | HZS605 |

Vibration Mode | Linear Motion | Linear Motion | Linear Motion | Linear Motion |

Capacity | 30L/S | 35L/S | 40L/S | 45L/S |

Screen Area | 2.2㎡ | 2.7㎡ | 2.7㎡ | 3.4㎡ |

Screen Qty & Size | 3×1050×700mm | 3×1080×830mm | 4×1165×585mm | 5×1165×585mm |

Motor Power | 2×1.5kW | 2×1.8kW | 2×2.2kW | 2×2.5kW |

Deck Angle Range | -1°~3° | -1°~3° | -1°~3° | -1°~3° |

Dimension: L×W×H | 2850×1590×1550 | 3150×1800×1630 | 2650×1700×1750 | 2850×1750×1650mm |

Weight | 1680kg | 1800kg | 1950kg | 2350kg |

Xi'an HL Petroleum Equipment Co., Ltd. produces various types of drilling fluid shale shakers. Please send inquiry to us sales@hlsolidscontrol.com.

Overview of linear shale shaker

Linear mud shale shaker is a first-stage equipment for solid-liquid separation of drilling fluid. It is suitable for drilling fluid solid control system of oil and gas drilling. Linear movement along a certain direction achieves the purpose of screening and discharging cuttings particles in drilling fluid.

Features of linear shale shaker

1. High efficiency of linear vibration trajectory.

2. Any combination of double, triple and quadruple.

3. The angle of the screen box can be adjusted to prevent the slurry from running out.

4. Hook edge plate screen, economical and affordable.

5. Screen box inclination adjustment device to prevent pulp running.

Technical parameters of linear shale shaker

Model | HZS703 | HZS803 | HZS604 | HZS605 |

Vibration Mode | Linear Motion | Linear Motion | Linear Motion | Linear Motion |

Capacity | 30L/S | 35L/S | 40L/S | 45L/S |

Screen Area | 2.2㎡ | 2.7㎡ | 2.7㎡ | 3.4㎡ |

Screen Qty & Size | 3×1050×700mm | 3×1080×830mm | 4×1165×585mm | 5×1165×585mm |

Motor Power | 2×1.5kW | 2×1.8kW | 2×2.2kW | 2×2.5kW |

Deck Angle Range | -1°~3° | -1°~3° | -1°~3° | -1°~3° |

Dimension: L×W×H | 2850×1590×1550 | 3150×1800×1630 | 2650×1700×1750 | 2850×1750×1650mm |

Weight | 1680kg | 1800kg | 1950kg | 2350kg |

Xi'an HL Petroleum Equipment Co., Ltd. produces various types of drilling fluid shale shakers. Please send inquiry to us sales@hlsolidscontrol.com.