| Name | Download |

|---|---|

| HL Product List.pdf | Download |

| Availability: | |

|---|---|

| Quantity: | |

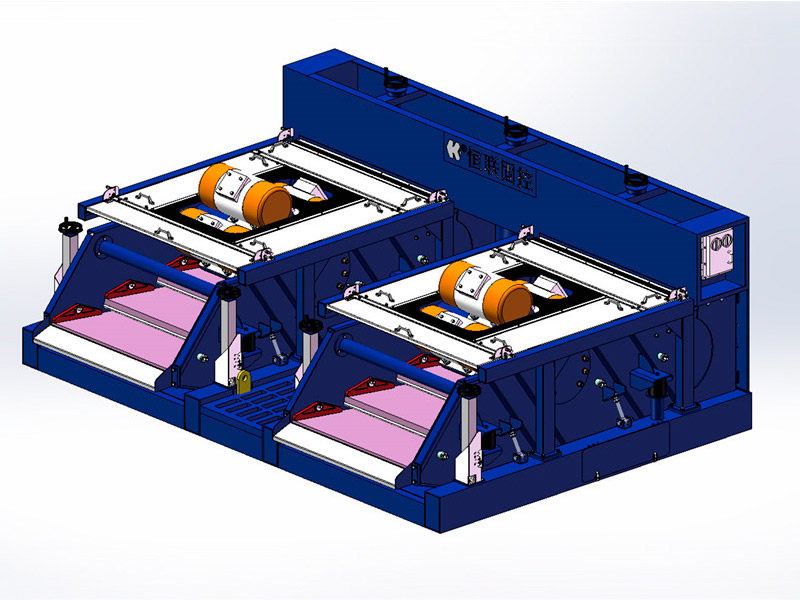

The introduction of Balanced Elliptical Motion Shale Shaker

The Balanced elliptical mud vibrating screen is a new type of mud vibrating device developed by our company based on many years of on-site practical experience. The vibrating screen can set the running track according to the needs of the site.

When the shift site needs to reduce the mud moisture content, the elliptical motion mode is turned on It can increase the residence time of mud on the screen surface, so as to achieve the purpose of reducing the solid moisture content.

When the wellhead mud volume is too large, the linear motion mode will be turned on, the processing capacity of the vibrating screen will increase, and the drilling fluid can be quickly cleaned.

The translational circular shale shaker produced by Xi'an HL has stable performance, low noise, and is suitable for various working conditions. Indispensable mud treatment equipment in modern drilling engineering.

Balanced Elliptical Motion Shale Shaker Technical Parameters

Model | HTZS804 | 2HTZS804 | HTZS605 | 2HTZS605 |

Vibration Mode | Elliptical | Elliptical | Linear/ Elliptical | Linear/ Elliptical |

Capacity | 35L/S | 70L/S | 45L/S | 90L/S |

Screen Area | 2.7㎡ | 5.4㎡ | 3.4㎡ | 6.8㎡ |

Screen Qty(Pcs)&Size | 4×1080×830mm | 8×1080×830mm | 5×1165×585mm | 10×1165×585mm |

Motor Power | 2.2+2.5kW | 2×(2.2+2.5)kW | 2×2.5+0.8kW | 2×(2×2.5+0.8)kW |

Deck Angle Range | -1°~3° | -1°~3° | -1°~3° | -1°~3° |

Dimension: L×W×H(mm) | 3150×1800×1630 | 3150×1800×1630 | 2850×1750×1650 | 2850×1750×1650 |

Weight | 2000kg | 4500kg | 2350kg | 4900kg |

The features of Balanced Elliptical Motion Shale Shaker

1. 3.4m super large filtration area.

2. The angle of the screen box is adjustable to prevent the slurry from running out.

3. Anti-splash design, clean and tidy.

4. The screen box heat treatment can cope with high-strength continuous work.

5. Linear and elliptical motion, suitable for more occasions

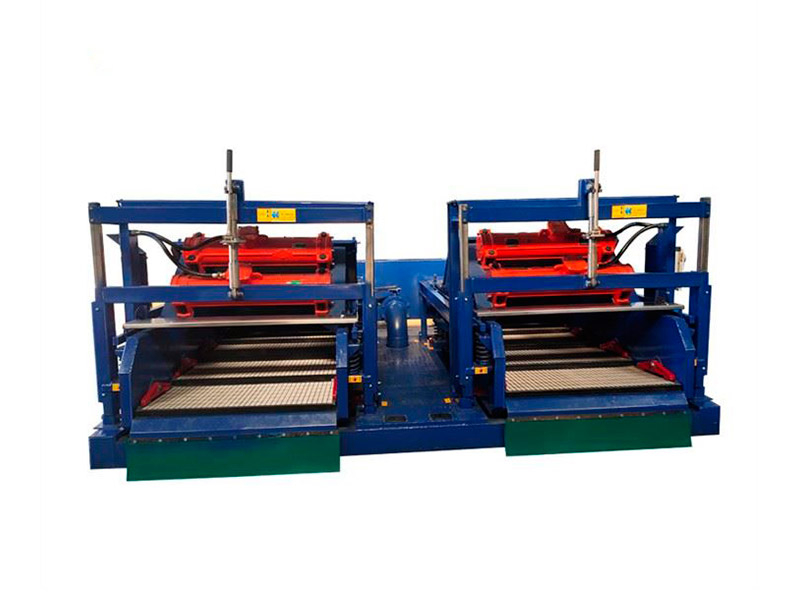

Finished picture of Balanced Elliptical Motion Shale Shaker

Practical application scenarios

The introduction of Balanced Elliptical Motion Shale Shaker

The Balanced elliptical mud vibrating screen is a new type of mud vibrating device developed by our company based on many years of on-site practical experience. The vibrating screen can set the running track according to the needs of the site.

When the shift site needs to reduce the mud moisture content, the elliptical motion mode is turned on It can increase the residence time of mud on the screen surface, so as to achieve the purpose of reducing the solid moisture content.

When the wellhead mud volume is too large, the linear motion mode will be turned on, the processing capacity of the vibrating screen will increase, and the drilling fluid can be quickly cleaned.

The translational circular shale shaker produced by Xi'an HL has stable performance, low noise, and is suitable for various working conditions. Indispensable mud treatment equipment in modern drilling engineering.

Balanced Elliptical Motion Shale Shaker Technical Parameters

Model | HTZS804 | 2HTZS804 | HTZS605 | 2HTZS605 |

Vibration Mode | Elliptical | Elliptical | Linear/ Elliptical | Linear/ Elliptical |

Capacity | 35L/S | 70L/S | 45L/S | 90L/S |

Screen Area | 2.7㎡ | 5.4㎡ | 3.4㎡ | 6.8㎡ |

Screen Qty(Pcs)&Size | 4×1080×830mm | 8×1080×830mm | 5×1165×585mm | 10×1165×585mm |

Motor Power | 2.2+2.5kW | 2×(2.2+2.5)kW | 2×2.5+0.8kW | 2×(2×2.5+0.8)kW |

Deck Angle Range | -1°~3° | -1°~3° | -1°~3° | -1°~3° |

Dimension: L×W×H(mm) | 3150×1800×1630 | 3150×1800×1630 | 2850×1750×1650 | 2850×1750×1650 |

Weight | 2000kg | 4500kg | 2350kg | 4900kg |

The features of Balanced Elliptical Motion Shale Shaker

1. 3.4m super large filtration area.

2. The angle of the screen box is adjustable to prevent the slurry from running out.

3. Anti-splash design, clean and tidy.

4. The screen box heat treatment can cope with high-strength continuous work.

5. Linear and elliptical motion, suitable for more occasions

Finished picture of Balanced Elliptical Motion Shale Shaker

Practical application scenarios