| Name | Download |

|---|---|

| HL Product List.pdf | Download |

| Availability: | |

|---|---|

| Quantity: | |

A drilling mud gun is a specialized equipment used in conjunction with a mud agitator to agitate drilling mud in the mud tank, specifically targeting the settled sand and dead corners.

The mud guns can be classified into two types based on their structure: fixed mud guns and rotary mud guns.

Rotary mud guns can further be divided into manually adjustable and self-rotating types. Manually adjustable mud guns include swing-type and rotating-type.

Rotary drilling mud guns need to be fixed on the top of the mud tank, with the gun barrel immersed in the drilling mud tank. The nozzle is positioned 200 to 300mm above the bottom of the mud tank. The rotation of the drilling mud is generated by the rotary motion of the mud gun, achieving the purpose of agitation. In most cases in China, manually adjustable rotary mud guns are used.

Fixed mud guns are more commonly used in drilling mud tanks of solid control systems abroad. They are installed diagonally at approximately 200mm above the bottom of the tank, with the nozzle parallel to the longitudinal wall of the mud tank, creating a rotational movement of the drilling mud layer. For example, the fixed mud gun used in the solid control system of an Ideal drilling rig in the United States is a fixed mud gun.

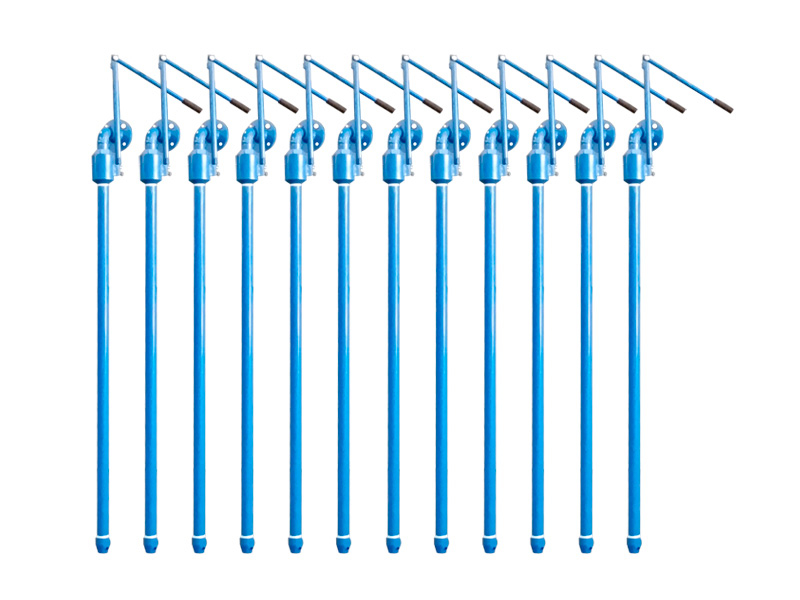

Drilling Mud Gun Pictures

Drilling Mud Gun Parameters

| Model | HNQ50 | HNQ65 | HNQ80 |

| Working Presure | <6.4MPa | <6.4MPa | <6.4MPa |

| Nozzle Qty | 1~3个 | 1~3个 | 1~3个 |

| Rotation Degree | 300° | 300° | 300° |

Drilling Mud Gun Features

1. Agitation Capability: Effectively agitates drilling mud to ensure uniform mixing and suspension.

2. Structure: Consists of a gun barrel, nozzle, and rotation mechanism.

3. Mud Circulation: Facilitates circulation by creating rotational movement to prevent solid settling.

4. Adjustable Nozzle: Allows for angle and direction adjustment of mud discharge.

5. Installation: Can be fixed or rotary.

6. Durability: Constructed with corrosion-resistant materials for harsh environments.

7. Ease of Maintenance: Components are easily maintained and cleaned.

8. Compatibility: Suitable for various types of drilling fluids and drilling applications.

A drilling mud gun is a specialized equipment used in conjunction with a mud agitator to agitate drilling mud in the mud tank, specifically targeting the settled sand and dead corners.

The mud guns can be classified into two types based on their structure: fixed mud guns and rotary mud guns.

Rotary mud guns can further be divided into manually adjustable and self-rotating types. Manually adjustable mud guns include swing-type and rotating-type.

Rotary drilling mud guns need to be fixed on the top of the mud tank, with the gun barrel immersed in the drilling mud tank. The nozzle is positioned 200 to 300mm above the bottom of the mud tank. The rotation of the drilling mud is generated by the rotary motion of the mud gun, achieving the purpose of agitation. In most cases in China, manually adjustable rotary mud guns are used.

Fixed mud guns are more commonly used in drilling mud tanks of solid control systems abroad. They are installed diagonally at approximately 200mm above the bottom of the tank, with the nozzle parallel to the longitudinal wall of the mud tank, creating a rotational movement of the drilling mud layer. For example, the fixed mud gun used in the solid control system of an Ideal drilling rig in the United States is a fixed mud gun.

Drilling Mud Gun Pictures

Drilling Mud Gun Parameters

| Model | HNQ50 | HNQ65 | HNQ80 |

| Working Presure | <6.4MPa | <6.4MPa | <6.4MPa |

| Nozzle Qty | 1~3个 | 1~3个 | 1~3个 |

| Rotation Degree | 300° | 300° | 300° |

Drilling Mud Gun Features

1. Agitation Capability: Effectively agitates drilling mud to ensure uniform mixing and suspension.

2. Structure: Consists of a gun barrel, nozzle, and rotation mechanism.

3. Mud Circulation: Facilitates circulation by creating rotational movement to prevent solid settling.

4. Adjustable Nozzle: Allows for angle and direction adjustment of mud discharge.

5. Installation: Can be fixed or rotary.

6. Durability: Constructed with corrosion-resistant materials for harsh environments.

7. Ease of Maintenance: Components are easily maintained and cleaned.

8. Compatibility: Suitable for various types of drilling fluids and drilling applications.