| Name | Download |

|---|---|

| HL Product List.pdf | Download |

| Availability: | |

|---|---|

| Quantity: | |

A drilling shear mixer, also known as a mud shear mixer or a drilling fluid shear mixer, is a specialized equipment used in the oil and gas industry during drilling operations. It is primarily used to mix drilling fluids, also known as drilling muds, which are crucial for maintaining wellbore stability and facilitating the drilling process.

The drilling shear mixer is designed to efficiently mix various components of the drilling fluid, such as water, base oil, viscosifiers, weight materials, and additives. These components are combined in specific proportions to create a properly balanced drilling fluid that meets the requirements of the drilling operation.

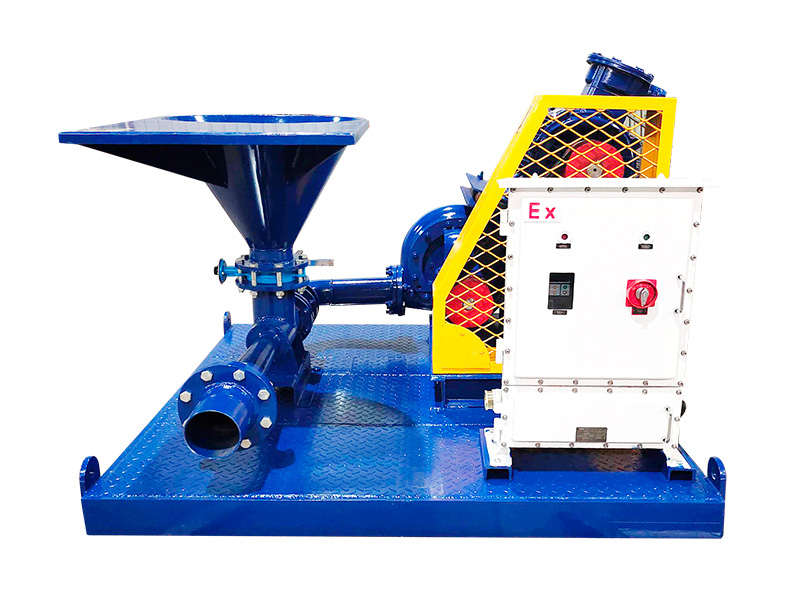

Drilling Shear Mixer Pictures

Drilling Shear Mixer Features

1. Mixing Tank or Hopper: Container for holding the drilling fluid during mixing.

2. Shear Blades or Paddles: Blades or paddles that create intense cutting forces and turbulence in the drilling fluid for thorough mixing and dispersion.

3. Variable Speed Controls: Allows operators to adjust the rotational speed of the shear blades for optimal mixing efficiency.

4. Centrifugal Pumps: Built-in pumps for continuous fluid circulation and prevention of sedimentation or settling.

5. Mixing Timer and Controls: Integrated timers and controls for setting specific mixing durations or sequences.

6. Safety Features: Emergency stop buttons, overload protection, and safety guards for operator safety.

7. Easy Maintenance and Cleaning: Accessible openings or hatches for inspection, cleaning, and maintenance, and self-cleaning mechanisms.

8. Robust Construction: Durable materials, such as stainless steel or corrosion-resistant alloys, for longevity and reliability.

A drilling shear mixer is a specialized equipment used in the oil and gas industry to thoroughly mix drilling fluids, ensuring the fluid's properties meet the requirements of the drilling operation.

A drilling shear mixer, also known as a mud shear mixer or a drilling fluid shear mixer, is a specialized equipment used in the oil and gas industry during drilling operations. It is primarily used to mix drilling fluids, also known as drilling muds, which are crucial for maintaining wellbore stability and facilitating the drilling process.

The drilling shear mixer is designed to efficiently mix various components of the drilling fluid, such as water, base oil, viscosifiers, weight materials, and additives. These components are combined in specific proportions to create a properly balanced drilling fluid that meets the requirements of the drilling operation.

Drilling Shear Mixer Pictures

Drilling Shear Mixer Features

1. Mixing Tank or Hopper: Container for holding the drilling fluid during mixing.

2. Shear Blades or Paddles: Blades or paddles that create intense cutting forces and turbulence in the drilling fluid for thorough mixing and dispersion.

3. Variable Speed Controls: Allows operators to adjust the rotational speed of the shear blades for optimal mixing efficiency.

4. Centrifugal Pumps: Built-in pumps for continuous fluid circulation and prevention of sedimentation or settling.

5. Mixing Timer and Controls: Integrated timers and controls for setting specific mixing durations or sequences.

6. Safety Features: Emergency stop buttons, overload protection, and safety guards for operator safety.

7. Easy Maintenance and Cleaning: Accessible openings or hatches for inspection, cleaning, and maintenance, and self-cleaning mechanisms.

8. Robust Construction: Durable materials, such as stainless steel or corrosion-resistant alloys, for longevity and reliability.

A drilling shear mixer is a specialized equipment used in the oil and gas industry to thoroughly mix drilling fluids, ensuring the fluid's properties meet the requirements of the drilling operation.