| Name | Download |

|---|---|

| HL Product List.pdf | Download |

| Availability: | |

|---|---|

| Quantity: | |

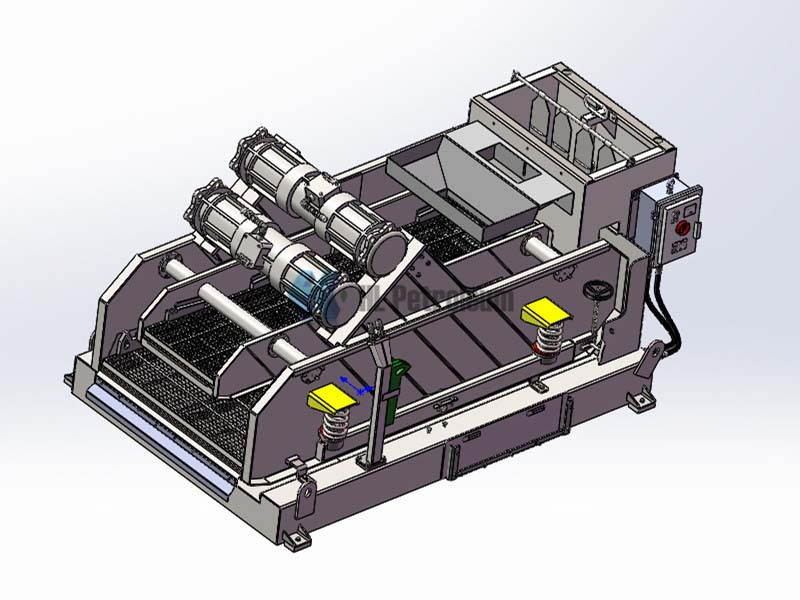

Laminated mud shale shaker is a set of shaker combination equipment specially designed to deal with large particles and sticky mud in drilling fluid. Before the drilling fluid enters the fine screen cloth, a coarse-grade protective screen is installed to accept the drilling fluid returning from the bell mouth, and to clean up sludge or larger particles.

Laminated Mud Shale Shaker Pictures

Laminated Mud Shale Shaker Parameters

| Model | HDZS6208 | HDZS6312 |

| Vibration Mode | Linear | Linear |

| Capacity | 60L/S | 80L/S |

| Screen Area | 5.2m² | 8.1m² |

| Screen Size | 12×650×600mm | 18×650×600mm |

| Motor Power | 2×2.5KW | 2×3.0KW |

| Deck Angle Range | -1°~5° | -1°~7° |

| Dimensions | 3000×1800×1750 | 3000×1800×2550 |

| Weight | 2500kg | 2800kg |

Laminated Mud Shale Shaker Components

The laminated mud shale shaker consists of a single-layer shale shaker directly installed on a double-layer shale shaker, and this combination is especially effective in drilling applications on offshore platforms where every inch of land is precious.

Laminated Mud Shale Shaker Application

Contact Us

Tel: +86-29-88680837

Fax: +86-29-88680975

Mobile/Whatsapp/Wechat: +86-13735815206

E-mail: sales@hlsolidscontrol.com

Laminated mud shale shaker is a set of shaker combination equipment specially designed to deal with large particles and sticky mud in drilling fluid. Before the drilling fluid enters the fine screen cloth, a coarse-grade protective screen is installed to accept the drilling fluid returning from the bell mouth, and to clean up sludge or larger particles.

Laminated Mud Shale Shaker Pictures

Laminated Mud Shale Shaker Parameters

| Model | HDZS6208 | HDZS6312 |

| Vibration Mode | Linear | Linear |

| Capacity | 60L/S | 80L/S |

| Screen Area | 5.2m² | 8.1m² |

| Screen Size | 12×650×600mm | 18×650×600mm |

| Motor Power | 2×2.5KW | 2×3.0KW |

| Deck Angle Range | -1°~5° | -1°~7° |

| Dimensions | 3000×1800×1750 | 3000×1800×2550 |

| Weight | 2500kg | 2800kg |

Laminated Mud Shale Shaker Components

The laminated mud shale shaker consists of a single-layer shale shaker directly installed on a double-layer shale shaker, and this combination is especially effective in drilling applications on offshore platforms where every inch of land is precious.

Laminated Mud Shale Shaker Application

Contact Us

Tel: +86-29-88680837

Fax: +86-29-88680975

Mobile/Whatsapp/Wechat: +86-13735815206

E-mail: sales@hlsolidscontrol.com